This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Moisture in the printed circuit board – effective detection with FT-IR

Small Cause – Huge Effect

Part 1: Moisture in Epoxy Resin

In this and the next article we will take a look at the impact of humidity on the production and storage process and how this influence can be detected by FT-IR spectrometry. Humidity is more than just moisture in the air. Water molecules interact with reactive components in the manufacturing process of epoxy resin matrix and solder resist, inhibiting their reactivity. The result is an epoxy resin matrix that is not fully crosslinked or a solder resist that cannot be effectively exposed. The effect of humidity is often not noticeable – at least not until the board fails. This failure can manifest itself in various ways, such as electromigration.

Moisture in the Manufacturing Process

So what does this have to do with the influence of humidity in the epoxy resin manufacturing process? Let’s take a look at what humidity can do to the epoxy resin manufacturing process. The epoxy resin of a printed circuit board essentially consists of a polymer matrix and a hardener. In addition, there are additives such as flame retardants and processing agents. The last-named regulate the curing or crosslinking process and ensure defined reaction conditions. The curing component (the crosslinker) is extremely reactive, and it is precisely what can become problematic if atmospheric moisture reacts with it before the polymer component can do this.

Moisture During Storage

Epoxy resins, like other polymers, absorb water molecules on contact with liquid or gaseous water, diffusing them into the polymer network. Hardly anyone knows it, but epoxy polymers absorb a few percent of water by weight. The water absorption depends on the following parameters:

- the chemical composition of the epoxy polymer

- the degree of crosslinking

- the thermal “history” of the polymer, e.g. caused by different curing conditions or (thermal) aging

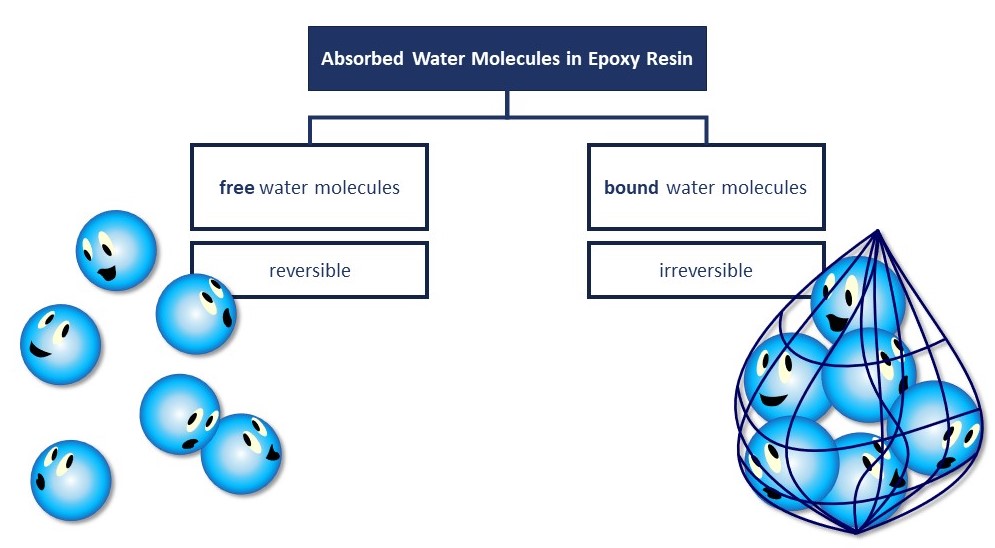

Now, when humidity is embedded in the PCB substrate, this happens in two ways. The first way is a physical inclusion of water molecules in the cavities of the PCB. Here we are talking about free water.

The second way is a chemical integration of the embedded water molecules into the molecular structure of the epoxy resin matrix. This is so-called bound water.

In practice, we find both free water and bound water in the epoxy resin matrix. Which material properties are influenced by air humidity in the printed circuit board?

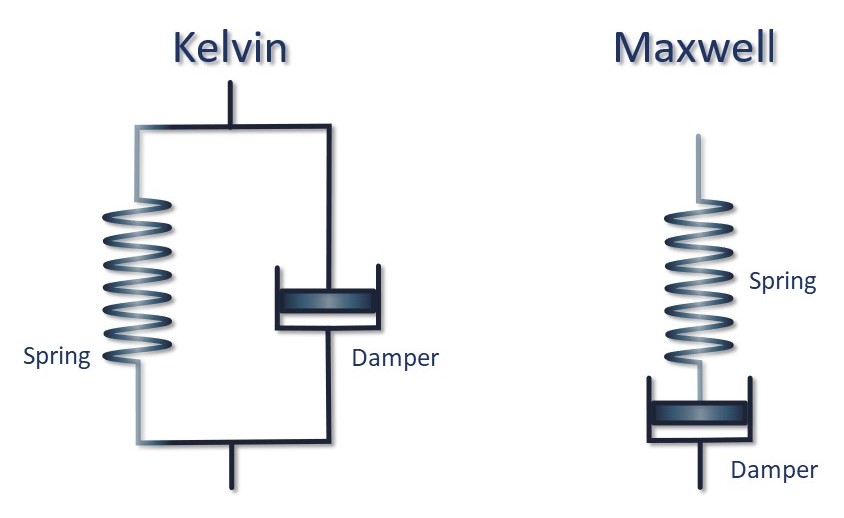

#1 Viscoelasticity

PCB substrate, like all polymers, has viscoelastic behavior. This means that both viscous and elastic behavior are present. The elastic portion basically causes spontaneous, limited, reversible deformation (like a spring). The viscous part basically causes a time-dependent, unlimited, irreversible deformation (like a damper). The best way to visualize this is with the help of Kelvin and Maxwell bodies. Kelvin body deforms time-dependently like a liquid, but limited and reversible like a solid. Maxwell body: there is a time-dependent, unlimited, irreversible deformation like a liquid, but there is also a time-independent and reversible spontaneous elastic component like a solid.

PCB substrate, like all polymers, has viscoelastic behavior. This means that both viscous and elastic behavior are present. The elastic portion basically causes spontaneous, limited, reversible deformation (like a spring). The viscous part basically causes a time-dependent, unlimited, irreversible deformation (like a damper). The best way to visualize this is with the help of Kelvin and Maxwell bodies.

Kelvin body deforms time-dependently like a liquid, but limited and reversible like a solid. Maxwell body: there is a time-dependent, unlimited, irreversible deformation like a liquid, but there is also a time-independent and reversible spontaneous elastic component like a solid.

#2 Young’s modulus

The Young’s modulus is a material property. It describes the relationship between mechanical stress and strain during the deformation of a solid body with linear elastic behavior.

- Young’s modulus is a material constant. Young’s modulus is not constant for plastics.

It depends on, for example, temperature, humidity, type of stress and speed of stress.

Humidity influences the material properties of a PCB

Free water molecules

- do not affect inter- or intramolecular interactions

- do not cause plastification or swelling of the polymer

- can be reduced again by drying

Bound water molecules

- weakens or disturbs the intermolecular interactions between the polymer chains.

- Promotes the mobility of the polymer segments,

- Causes change in epoxy polymer e.g. in the form of swelling and plastification.

- Causes a decrease in the glass transition temperature by 5 to 30K.

- Causes a decrease in the Young’s modulus by 10 to 40%.

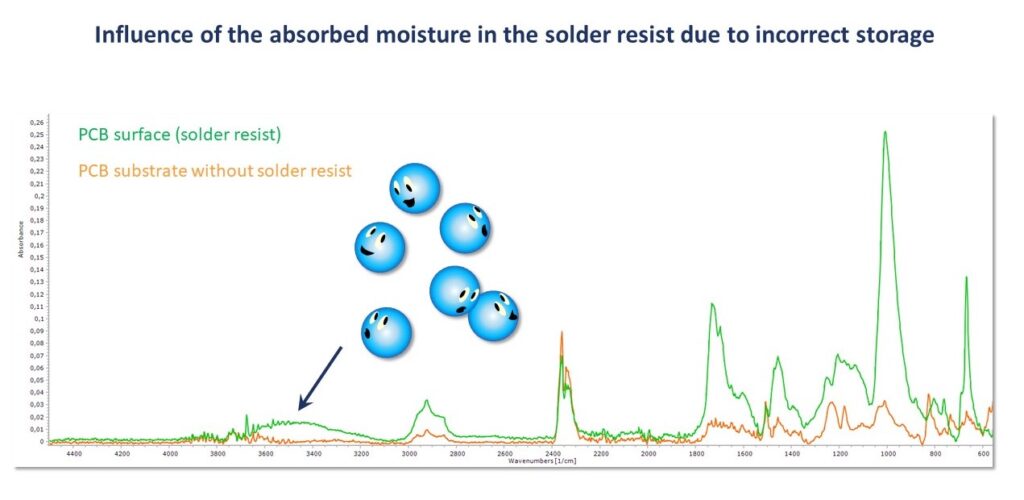

Neither optical nor electrical test methods can detect moisture penetration. Because the water molecules cannot be seen under the microscope. An electrical test will also not detect moisture absorbed by the substrate. FT-IR measurement is a fast and reliable method to identify if a PCB substrate has moisture absorption and how much it affects the quality of the PCB substrate.

Here we can see two measurements of a PCB – with and without solder resist. The green spectrum shows a water molecules (free water) in the surface of the solder resist. The orange spectrum (PCB surface under the solder resist) shows no inclusion of water molecules. This PCB batch was stored incorrectly and not dried sufficiently. The entire analysis, including removal of the solder resist, took 10 – 12 min. The result is very clear. Analogously, of course, water bound in the polymer or non-crosslinked epoxy because of the humidity during production can also be identified. Therefore, please identify early and react in time!